Welcome to the REVIPOX Blog, where we share knowledge, innovation, and field experience in epoxy pipe rehabilitation. Here you’ll find technical insights, news about internal coating technologies, and real project examples with no-dig solutions. Follow us and discover how we bring new life to pipelines.

Continuous internal rehabilitation in ageing pipe systems

When joint seals degrade across a pipe system, continuous internal rehabilitation restores watertightness and extends service life without full replacement.

Read More

Old joint seals in plastic pipes

PVC joints may appear intact during inspection yet still allow infiltration. This article explains the ageing process, warning signs, and appropriate technical solutions.

Read More

Rehabilitate or Replace Building Drains? What to Assess Before Deciding

Replace or rehabilitate drainage stacks? Learn what should be assessed before starting major building works.

Read More

Old drains: risks, signs of degradation and alternatives to replacement

Understand the risks of old pipe stacks and when internal rehabilitation may be an alternative to full replacement.

Read More

Repairing pipes without major works: when it is possible and when it is not

Learn when pipes can be repaired without major works and when traditional replacement is the only safe option.

Read More

Water leaks in buildings: causes, diagnosis and no-dig solutions

Understand the real cause of water leaks in buildings and learn when no-dig repair solutions may be possible.

Read More

Repair of internal water leaks without demolition

Internal pipe leaks can hide inside walls and ceilings, causing damage long before they become visible. With REVIPOX’s trenchless epoxy rehabilitation, pipes can be repaired and renewed from the inside, without demolition, dust, or disruption.

Read More

Rehabilitation of Rainwater Drain Pipes

Rainwater drain pipes often deteriorate silently, causing infiltrations and structural damage that only become visible when the problem is serious. With REVIPOX’s trenchless epoxy rehabilitation, buildings can restore and protect their pluvial systems quickly, without demolition, noise, or disruption to residents.

Read More

Different curing methods for epoxy CIPP repairs and renovations

The curing stage is the most crucial moment in any CIPP rehabilitation — it’s when the resin turns into a solid new wall inside the pipe. Discover the different epoxy resin curing methods, from ambient curing to modern UV and LED technologies

Read More

CIPP and UV curing: faster and cleaner pipe rehabilitation

The CIPP system with ultraviolet (UV) light curing is changing the way pipelines are rehabilitated. It’s a fast, clean, and fully controlled process that restores pipes without digging or disrupting service.

Read MoreContacto e pedido de diagnóstico

Problemas nas tubagens? Podemos ajudar sem obras.

The REVIPOX Process

Our method is simple, fast, and transparent — designed to solve pipeline problems without digging or demolition.

Service request

Choose the service you need or describe your problem. Our team collects the details and schedules a technical visit.

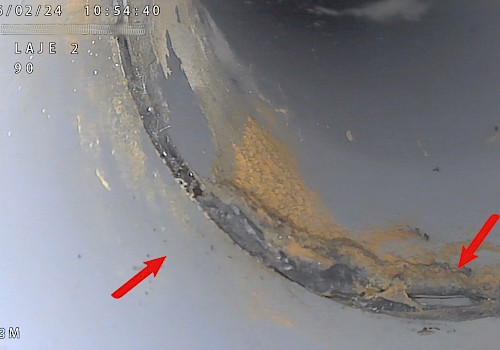

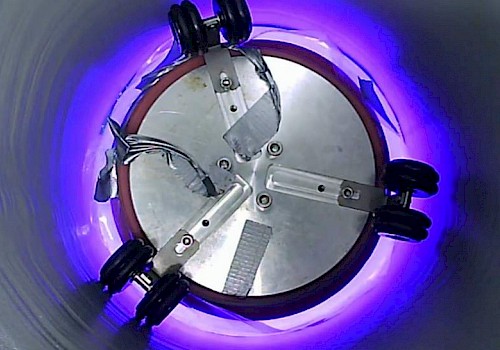

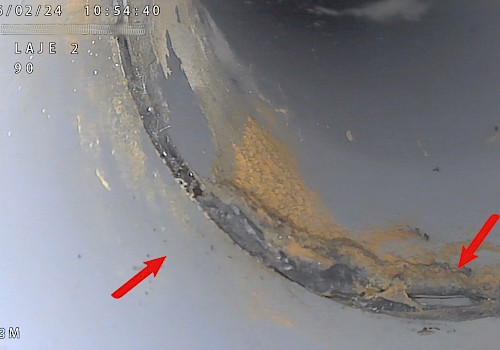

Inspection and diagnosis

We perform a high-definition video inspection to assess the internal condition of the pipes and detect cracks, corrosion, or blockages.

Rehabilitation plan

Based on the diagnosis, we provide a custom rehabilitation plan with the best epoxy solution — including cleaning, preparation, and internal coating.

Application and validation

We apply the epoxy coating and conduct a second inspection to verify adhesion and tightness. Pipes renewed, no digging, and ready to last for decades.

Partnerships that strengthen REVIPOX

At REVIPOX, we believe that innovation and quality are built through collaboration. We work hand in hand with specialized partner companies — including Desentopesgotos, Clean Esgotos and Servilar — who share our vision of delivering advanced and sustainable technical solutions. Through these partnerships, we combine experience, technology, and responsiveness to ensure a complete service — from inspection to full pipeline rehabilitation.

What Our Clients Say

Clients across Portugal trust REVIPOX to restore their pipeline systems quickly, cleanly, and without demolition. Our epoxy internal coating technology brings reliability and peace of mind to residential, commercial, and industrial properties.

Latest News & Articles from REVIPOX

Follow the REVIPOX Blog to explore the latest updates in epoxy pipe rehabilitation, trenchless technology, and modern solutions for aging pipeline systems. We share technical tips, real case studies, and industry insights for those who want to stay informed about innovation in pipeline restoration.

Continuous internal rehabilitation in ageing pipe systems

When joint seals degrade across a pipe system, continuous internal rehabilitation restores watertightness and extends service life without full replacement.

Read More

Old joint seals in plastic pipes

PVC joints may appear intact during inspection yet still allow infiltration. This article explains the ageing process, warning signs, and appropriate technical solutions.

Read More

Rehabilitate or Replace Building Drains? What to Assess Before Deciding

Replace or rehabilitate drainage stacks? Learn what should be assessed before starting major building works.

Read More