CIPP and Packers: localized pipe repair without excavation

For decades, repairing a damaged pipe meant demolition, noise, and disruption. Fortunately, technology has evolved — and today it’s possible to rehabilitate pipelines without digging or breaking walls. One of the most effective techniques is CIPP (Cured In Place Pipe), and within this system there’s a more precise, localized version known as repair with packers.

What a packer is and how it works

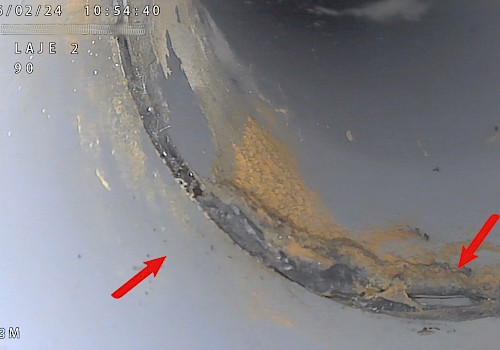

The system is based on a simple but highly effective concept. A packer is a flexible rubber balloon covered with a sleeve impregnated with epoxy resin. This unit is inserted inside the pipe and positioned exactly where there’s a crack, leak, or damaged joint.

When the packer is inflated with compressed air or water, usually at pressures between 0.5 and 2.5 bar, the resin sleeve molds perfectly to the inner walls of the pipe. After curing — which can take between 30 minutes and 2 hours, depending on the diameter and resin type — the packer is deflated and removed, leaving behind a new, solid, and watertight section inside the original pipe.

Advantages of this method

The great advantage of the CIPP packer system is its precision. Instead of replacing several meters of pipeline because of a small crack, you can repair only the affected area, without excavation or heavy works.

The process is quick, clean, and quiet — ideal for residential buildings, condominiums, and difficult-to-access locations. It also allows old pipelines made of stoneware, cast iron, or PVC to be restored and reinforced, extending their lifespan for decades.

Limitations and necessary care

Like any technology, this one also has its limits. The packer method is designed for localized damage; when there are multiple defects or widespread deterioration, a continuous CIPP rehabilitation is the best option.

Another key factor is the experience of the team. The packer’s positioning, inflation pressure, and curing time must all be calibrated precisely. A wrong pressure or incomplete curing process can compromise adhesion and reduce durability.

The importance of technical execution

At REVIPOX, we treat every intervention as a precision task. Each packer is placed using exact measurements and monitored in real time through video inspection. The result is a discreet, clean, and long-lasting repair that restores the pipe’s original strength and watertightness — without invasive construction work.

REVIPOX – The new life of pipelines begins from within.