CIPP and UV curing: faster and cleaner pipe rehabilitation

The CIPP (Cured In Place Pipe) rehabilitation technology keeps evolving, and one of the most promising innovations today is ultraviolet (UV) light curing. This method allows damaged pipelines to be restored even faster, cleaner, and with better control — without any excavation or long drying times.

How UV curing works

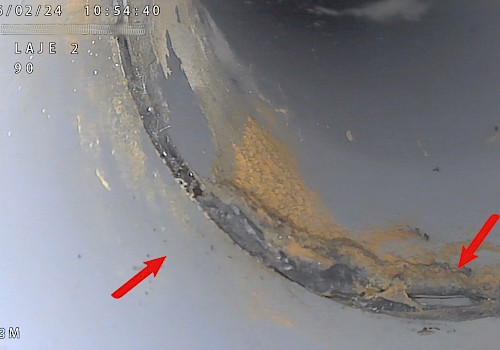

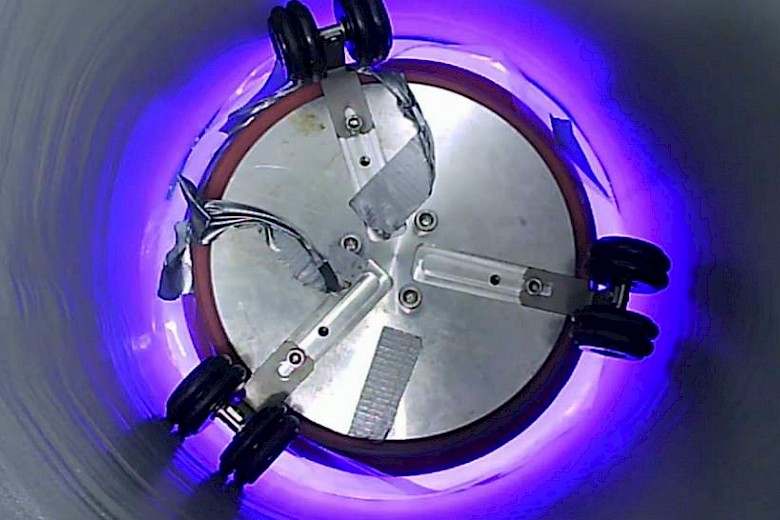

After cleaning and video inspection, a liner impregnated with a special resin is inserted into the pipe and positioned along the section to be repaired. Instead of using hot air, steam, or water to harden the resin, the process uses UV lamps mounted on a cable system or mobile robotic unit.

As the lamps travel through the inside of the pipe, the light activates the curing process, forming a new watertight inner wall. The entire operation is monitored in real time, and curing can be completed in just a few minutes per meter, depending on the diameter and type of resin used.

Advantages of the UV system

The main advantage of UV curing is speed. Since there’s no heating involved, total work time is drastically reduced, and the line can return to service the same day.

Another key benefit is quality control: the operator can visually monitor and record the entire process, ensuring the resin cures evenly along the whole length. Moreover, this technology is compatible with different types of resins — epoxy, polyester, or vinyl ester — allowing it to be adapted to the specific conditions of each project.

When to use UV curing

CIPP rehabilitation with UV curing is ideal for sewer, stormwater, or industrial pipelines, where access is difficult and downtime must be minimized. It’s also an excellent solution for urban areas where excavation or traffic disruption is not an option.

At REVIPOX, we are adopting this technology because it’s more affordable than LED curing systems, while still offering excellent durability and chemical resistance. It represents the next step in our ongoing commitment to innovation and to cleaner, more sustainable solutions.

REVIPOX – The new life of pipelines begins from within.