CIPP Epoxy Lining — How the Method Creates a New Pipe Inside the Old One

What is the CIPP (Cured-In-Place Pipe) method

The CIPP (Cured-In-Place Pipe) technology, also known as “pipe cured in place,” is one of the most advanced solutions in trenchless pipeline rehabilitation.

Instead of replacing damaged pipes, the method builds a new structural lining inside the existing pipe, restoring its integrity and performance without any excavation or demolition.

Using epoxy resin coating, the process transforms the old pipeline into a single, seamless, and watertight system — a new pipe within the old one — that can last more than 50 years.

Step-by-step: How the CIPP Epoxy process works

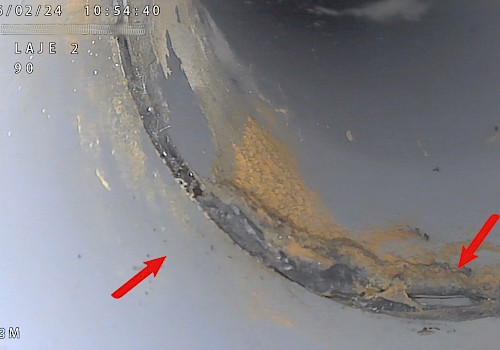

1. Inspection and diagnosis

Before rehabilitation begins, an HD CCTV video inspection is carried out to assess the internal condition of the pipe and identify damage such as corrosion, leaks, or deformation.

2. Cleaning and preparation

The internal surface is cleaned using rotary brushes or pressurized air/water jets.

This removes rust, deposits, and buildup, ensuring perfect adhesion between the resin and the pipe wall.

3. Liner impregnation

A flexible technical fabric liner is impregnated with high-strength, two-component epoxy resin formulated to create a new internal structural wall.

4. Insertion and inversion

The liner is inserted into the existing pipe and inverted using air or water pressure, making it adhere tightly to the internal surface.

5. Curing

The curing process is performed with hot air, steam, or UV light, depending on the resin type and pipe diameter.

During curing, the resin hardens to form a self-supporting, watertight structure.

6. Final inspection

After full curing, a second CCTV inspection confirms the uniformity, adhesion, and defect-free result.

The outcome is a fully rehabilitated pipeline ready for decades of reliable use.

Advantages of the CIPP method with epoxy

-

No digging or demolition required — perfect for buildings, condominiums, and urban areas

-

Lifespan over 50 years, resistant to corrosion and chemicals

-

Compatible with all materials — cast iron, copper, PVC, concrete, and more

-

Reduces costs and repair time

-

Improves hydraulic flow thanks to a smoother internal surface

-

100% watertight and structurally reinforced

Practical applications

CIPP technology is suitable for:

-

Sewer, wastewater, and stormwater lines

-

Buried and industrial pipelines

-

Vertical and horizontal risers in condominiums

-

Old or hard-to-access networks

In Portugal, REVIPOX applies the CIPP method using certified European epoxy resins and specialized equipment.

Why choose the REVIPOX CIPP method

The REVIPOX approach to CIPP combines technical expertise, precision equipment, and premium epoxy resins engineered for Portuguese infrastructure and climate.

It restores entire pipeline networks in just 1 to 3 days, with no noise, no debris, and no shutdowns.

REVIPOX — We create a new pipe inside the old one.