The evolution of epoxy resin pipe rehabilitation

From traditional repair to smart pipeline restoration

For decades, pipe repair inevitably meant construction work, demolition, and full replacement of damaged lines. Whenever a vertical stack, buried conduit, or sewer network developed leaks, the only solution was to break through walls or dig up the ground — a slow, costly, and highly invasive process.

It was only over the last three decades that the concept of epoxy resin pipe rehabilitation began to transform the sector, offering a modern, clean, and durable alternative to traditional replacement.

How internal pipe rehabilitation technology began

The internal coating method using epoxy resins first appeared in the 1980s in Northern Europe and the United States, as a response to the deterioration of aging supply and drainage networks.

The idea was simple yet revolutionary: to create a new inner wall within the existing pipe — fully bonded, watertight, and corrosion-resistant.

Over time, technology evolved, and several different methods emerged — from continuous epoxy spray lining to CIPP (Cured In Place Pipe) systems, where a resin-impregnated liner is cured in place, forming a new pipe within the old one.

The main technologies used today

Today, pipe rehabilitation and restoration can be carried out through several methods, adapted to the network type, material, and diameter:

Epoxy internal coating (Spray or Brush Lining):

Ideal for residential networks, vertical stacks, and small-diameter pipes. The resin is sprayed inside the pipeline, forming a continuous protective layer.

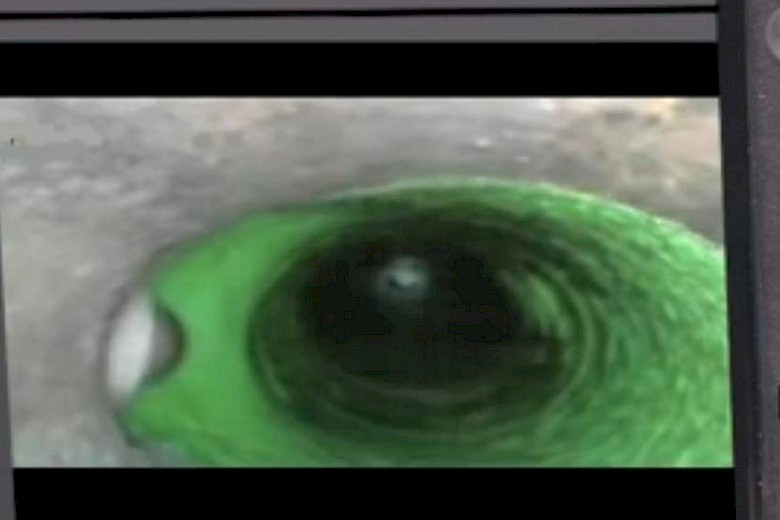

CIPP Epoxy Lining (Cured In Place Pipe):

Used mainly in underground or industrial conduits. The epoxy liner is inserted and cured with hot air or steam, forming a self-supporting structure inside the original pipe.

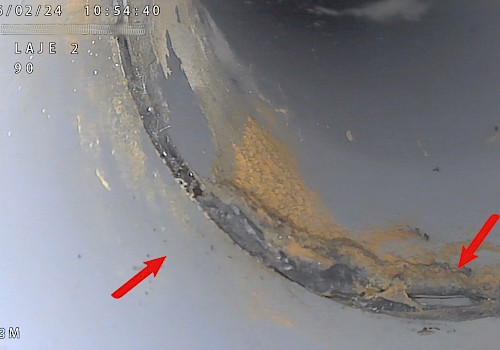

Partial rehabilitation with structural resins:

Recommended for localized repairs of leaks, cracks, or damaged joints, without the need to restore the entire length of the pipeline.

Hybrid coatings and advanced materials:

New formulas combine epoxy resins with polymers and fiberglass reinforcements, ensuring greater flexibility and mechanical strength.

Advantages over traditional replacement

Epoxy resin internal rehabilitation has become the preferred solution for engineers, property managers, and industrial companies for several clear reasons:

-

No need for demolition or excavation

-

Reduces intervention time by up to 80%

-

Ensures full watertightness and chemical resistance

-

Extends the lifespan of pipelines by several decades

-

Improves hydraulic flow and minimizes the risk of new ruptures

The REVIPOX Group commitment

At REVIPOX, we believe that innovation is the true driving force behind modern pipeline restoration.

As a group of companies with consolidated experience — including Desentopesgotos, Clean Esgotos and Servilar — we continuously invest in training, technology, and state-of-the-art equipment to deliver the best technical performance and value on the market.

Each project represents more than just a repair: it’s an opportunity to give pipelines a new life — through sustainable, fast, and long-lasting solutions.

REVIPOX — The new life of pipelines begins from within.