The Future of Pipeline Rehabilitation — Why Epoxy Is Changing Everything

A silent revolution inside the pipes

For decades, repairing pipelines meant breaking walls, digging floors, and replacing old pipes — a process that was slow, messy, and expensive.

Today, epoxy technology is transforming that reality, and internal pipe rehabilitation has become the modern, clean, and sustainable alternative to restore water and wastewater networks without construction work.

At REVIPOX, we believe the future of building maintenance lies in trenchless solutions that combine technical performance, durability, and environmental responsibility.

The epoxy internal coating method is at the heart of this revolution.

What is epoxy internal coating

Epoxy coating involves applying a continuous protective layer inside existing pipelines.

This layer hardens to form a new internal wall that is resistant to pressure, corrosion, and leaks.

The process transforms an old, weakened pipe into a renewed and watertight conduit, ready for decades of new use.

Depending on the network type, epoxy can be applied through spraying, mechanical rotation, or the CIPP (Cured-In-Place Pipe) system — a technology that “cures” a resin-impregnated liner directly inside the existing pipe.

Why the epoxy method is gaining ground

The growing popularity of epoxy in Europe and Portugal can be explained by three key factors:

1. No demolition and faster repairs

Epoxy rehabilitation is non-invasive — it doesn’t require opening walls, digging, or interrupting daily use.

Within a few hours, it’s possible to repair internal leaks, reinforce vertical risers, or rehabilitate entire networks.

2. Extended lifespan

Modern epoxy resins offer mechanical and chemical resistance superior to galvanized steel or PVC.

Laboratory tests show a service life exceeding 50 years, without corrosion or cracks.

3. Sustainability

Rehabilitating is more eco-friendly than replacing.

It avoids material waste and significantly reduces the carbon footprint associated with manufacturing and transporting new pipes.

How the internal epoxy rehabilitation process works

The REVIPOX method follows several controlled steps to ensure precision and long-lasting quality:

-

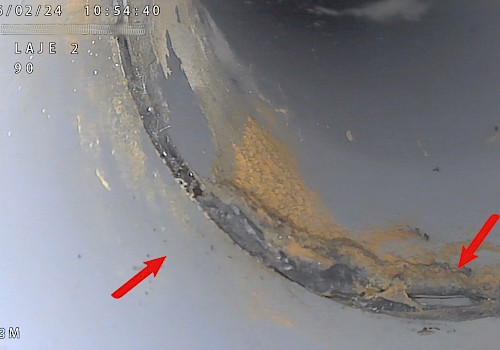

HD Video Inspection (CCTV) — evaluates internal condition and locates leaks or corrosion.

-

Mechanical Cleaning and Drying — removes debris, rust, and humidity.

-

Epoxy Application — resin is evenly distributed by rotation, spray, or CIPP liner.

-

Curing and Final Inspection — the resin hardens, forming a new watertight internal wall.

-

Final Technical Report — provided to the client with video evidence and detailed documentation.

Each step is video-monitored and executed by trained technicians using specialized equipment.

Advantages for buildings and condominiums

The epoxy method is especially advantageous for:

-

Vertical risers — no wall openings or inconvenience to residents.

-

Buried conduits — no digging or structural disruption.

-

Aged pipe systems — iron, copper, or PVC pipes restored to full function.

-

Commercial properties and hotels — quick, clean interventions with minimal downtime.

In most cases, work can be completed while the building remains operational, avoiding disruption or loss of revenue.

Epoxy vs. traditional replacement

| Criterion | Traditional Method | Epoxy Rehabilitation |

|---|---|---|

| Intervention | Destructive (requires demolition) | Non-invasive (no demolition) |

| Average duration | Weeks | 1–3 days |

| Lifespan | 10–20 years | 50+ years |

| Total cost | High (labor + reconstruction) | Lower |

| Environmental impact | High | Minimal |

| Leak guarantee | Limited | Total |

REVIPOX — The new life of pipelines

REVIPOX is a Portuguese company specialized in internal epoxy pipe lining and CIPP trenchless rehabilitation systems.

With trained teams and advanced equipment, we deliver complete solutions — from inspection to certified restoration — for residential, commercial, and industrial buildings.

We believe in a new way of maintaining infrastructure: no destruction, no waste, and results that last for decades.

REVIPOX — Rehabilitate from within. Protect for decades.