Fast interventions with no demolition required

Pipe Video Inspection

High-definition diagnostics for accurate rehabilitation planning

Before restoring a pipeline, it’s essential to understand its internal condition.

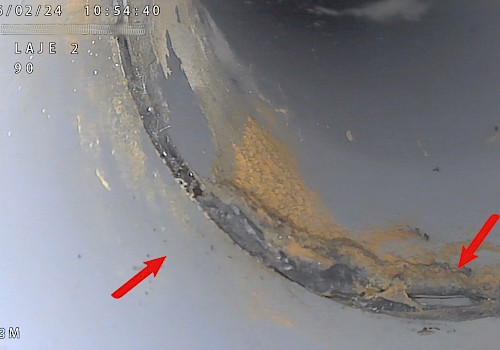

At REVIPOX, we use HD video inspection cameras to visualize every centimeter of the pipe system — identifying cracks, corrosion, infiltrations, and blockages that aren’t visible from the outside.

This advanced diagnostic step allows our specialists to design precise and non-invasive rehabilitation plans, avoiding unnecessary works and ensuring lasting results.

How the inspection works

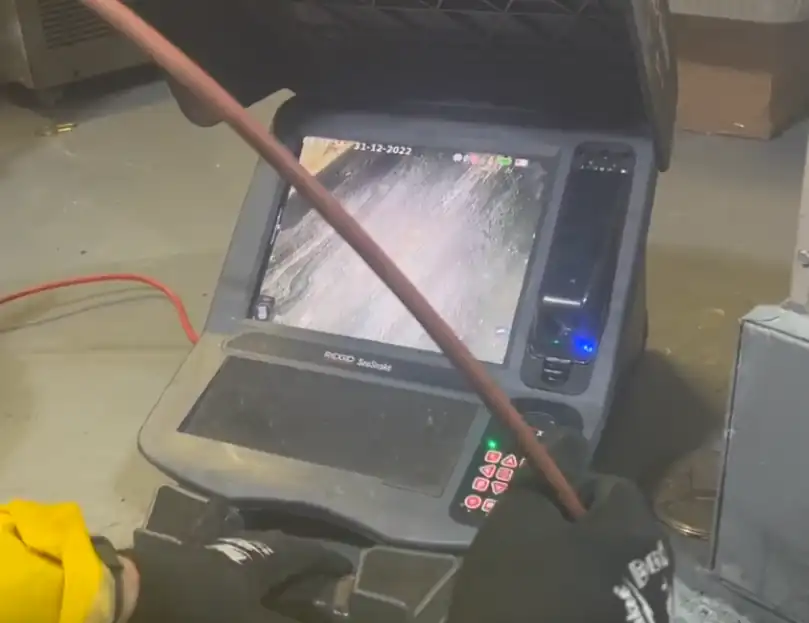

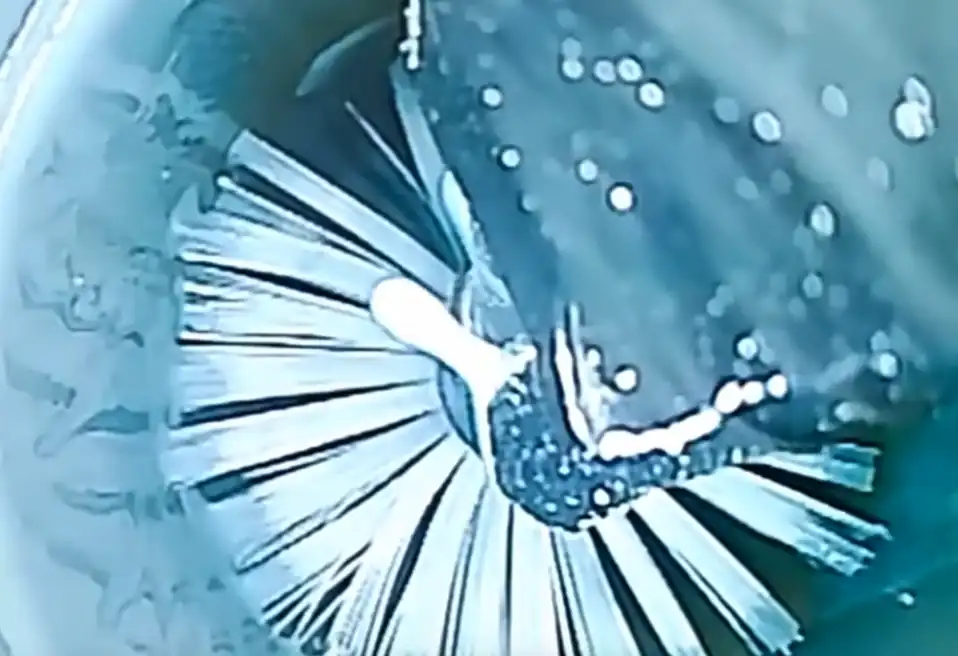

Our CCTV (Closed-Circuit Television) video inspection system uses high-resolution rotating cameras mounted on flexible cables that can navigate through pipes of different diameters.

During the inspection, the camera records the entire internal surface of the pipeline in real time, allowing our technicians to:

-

Detect cracks, leaks, corrosion, and root intrusion

-

Identify points of obstruction or material buildup

-

Evaluate pipe deformation or structural collapse

-

Produce a detailed video report and technical recommendation

Applications

The REVIPOX video inspection service is suitable for all types of installations:

-

Water supply lines

-

Drainage and wastewater systems

-

Rainwater and stormwater networks

-

Industrial or commercial plumbing systems

Whether it’s a residential building, condominium, or industrial facility, this technology allows us to analyze the entire network without excavation — saving time, money, and structural integrity.

Benefits of REVIPOX Video Inspection

-

Non-invasive and precise diagnostics

-

HD video recording with visual reports

-

Early detection of corrosion and leaks

-

Accurate planning for rehabilitation or epoxy lining

-

Reduced downtime and repair costs

At REVIPOX, we follow the EN 13508 standard, which defines the technical procedures for inspection, evaluation, and defect coding in drainage and sewer networks. This standard ensures that every diagnostic is carried out in a consistent and comparable way, allowing each crack, infiltration, or deformation to be identified and classified with precision. As a result, the final report is not just a recording — it’s a technical document with standardized codes and descriptions, serving as the basis for planning rehabilitation and proving the actual condition of the pipeline to authorities or insurance companies.

During the inspection, we use certified software compatible with the EN 13508 standard, such as WinCan, which is widely used by companies and municipalities across Europe. This system allows us to record every defect with its proper code, along with images, measurements, and exact location. In the end, we provide the client with a digital file that’s widely recognized and easy to use, so it can be shared with engineers, city services, or insurance companies without any compatibility issues. It’s a simple way to keep everything documented and ready for future repairs or maintenance.

From inspection to solution

Once the inspection is complete, our team prepares a technical report that includes high-resolution footage, observations, and the most suitable solution — whether it’s cleaning, internal preparation, or full epoxy relining.

Video inspection is only as good as the eyes and hands behind it. At REVIPOX, we believe that a detailed inspection depends not just on having a camera inside the pipe, but on using the right tools — high-resolution cameras, precise illumination, and flexible push rods that reach every curve. Just as important is the experience of the technician interpreting the images. A trained professional knows how to identify the smallest cracks, fissures, or early signs of corrosion that less-experienced eyes might miss. The result is a complete and reliable report that becomes the foundation for an accurate rehabilitation plan.

At REVIPOX, every successful rehabilitation starts with an accurate inspection.

Industrial video inspection

In industrial environments, video inspection plays a crucial role in preventing costly downtime and unexpected failures. At REVIPOX, we use high-resolution robotic crawlers and pan-and-tilt cameras capable of covering long pipe sections, bends, and junctions. These systems allow us to inspect pipelines under complex conditions — from factory drainage to process water networks — without interrupting production. Every inspection is analyzed by experienced technicians who prepare a clear report with images and video references, helping facility managers plan maintenance or rehabilitation before small defects turn into serious problems.

100%

Guaranteed Satisfaction

We rehabilitate pipelines, we restore confidence

REVIPOX is a company specialized in internal epoxy pipe coating, a technology that allows the restoration of aging pipelines without demolition. With trained teams and state-of-the-art equipment, we bring back functionality, durability, and safety to water and wastewater systems in residential, commercial, and industrial buildings.

-

-

Certified technology and long-lasting materials

-

Solutions adapted to every network type and diameter (32 mm to 300 mm)

The REVIPOX Method - New Life For Your Pipes

Contacto e pedido de diagnóstico

Problemas nas tubagens? Podemos ajudar sem obras.

Complete solutions for internal pipe rehabilitation

At REVIPOX, we operate across all stages of the rehabilitation process — from initial inspection to final epoxy coating. Each service is carried out by specialized technicians using advanced technology, ensuring long-lasting results without the need for demolition.

Pipe Video Inspection

High-definition visual diagnostics using HD video cameras to assess the internal condition of the pipes and identify cracks, leaks, or corrosion before intervention.

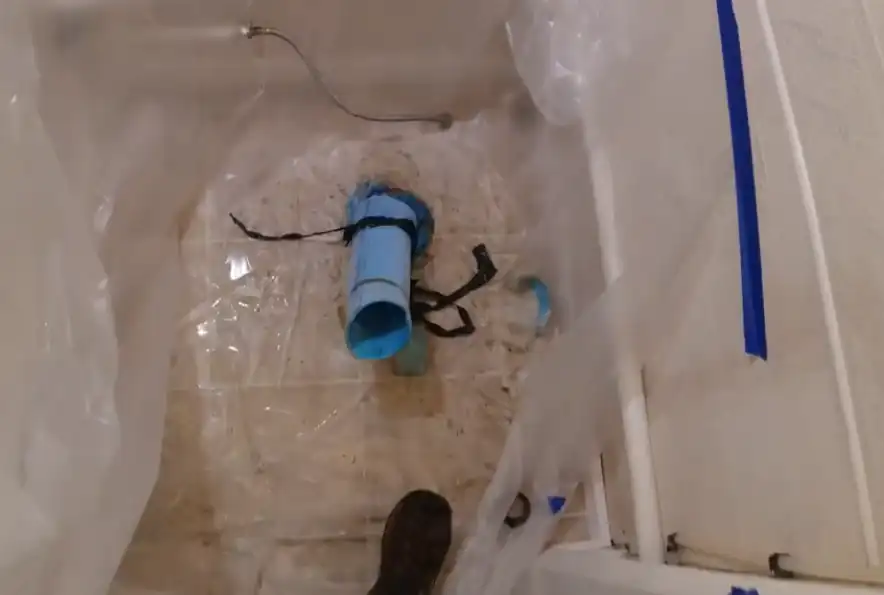

Mechanical Cleaning and Internal Preparation

We remove scale, debris, and corrosion through controlled brushing and jetting, preparing the pipe surface for perfect epoxy adhesion.

Epoxy Internal Coating

Application of a continuous internal epoxy lining that creates a new protective wall inside the pipe, sealing leaks and preventing future ruptures.

Vertical Pipe and Riser Rehabilitation

An ideal solution for buildings and condominiums, allowing the renewal of vertical water and wastewater risers without opening walls or disrupting residents. Fast, clean, and completely trenchless.

Buried Pipeline Rehabilitation

Internal coating of underground sewer, drainage, or stormwater pipes, eliminating leaks and maintaining structural integrity — no excavation required.

Localized Repairs and Leak Sealing

Targeted repair of internal ruptures, damaged joints, or small leaks using high-adhesion structural resins — a quick, clean, and long-lasting solution.

Why to choose REVIPOX?

Trust the experts who bring new life to your pipelines.

REVIPOX combines technology, precision, and experience to deliver long-lasting epoxy pipe rehabilitation solutions — with no need for demolition. Our work is based on detailed diagnostics, certified materials, and qualified technicians who ensure results that last.

Experienced Team

Our specialists are trained in internal epoxy coating and use advanced inspection and application equipment to guarantee top-quality results every time.

Trusted and Transparent

From the first contact to project completion, we value clear communication and trust. Every client receives a technical report and full professional support throughout the process.

Latest News & Articles from REVIPOX

Follow the REVIPOX Blog to explore the latest updates in epoxy pipe rehabilitation, trenchless technology, and modern solutions for aging pipeline systems. We share technical tips, real case studies, and industry insights for those who want to stay informed about innovation in pipeline restoration.

Continuous internal rehabilitation in ageing pipe systems

When joint seals degrade across a pipe system, continuous internal rehabilitation restores watertightness and extends service life without full replacement.

Read More

Old joint seals in plastic pipes

PVC joints may appear intact during inspection yet still allow infiltration. This article explains the ageing process, warning signs, and appropriate technical solutions.

Read More

Rehabilitate or Replace Building Drains? What to Assess Before Deciding

Replace or rehabilitate drainage stacks? Learn what should be assessed before starting major building works.

Read More