Fast interventions with no demolition required

REVIPOX Services — Complete Internal Pipeline Rehabilitation Solutions

Internal pipe rehabilitation has become, in recent years, the smartest way to fix ageing or damaged pipelines without demolition and without disturbing people living in the building. At REVIPOX, our main focus is to help apartment buildings, property administrators, and homeowners protect their properties with modern, safe, and low-disruption solutions that actually make sense for each situation.

We understand that deciding whether to repair or rehabilitate a pipeline isn’t always easy. It involves budget, impact on the building, time, and the fear of “Are they going to break everything?”. That’s why we work with a very transparent approach: we assess first, we explain clearly, and only then do we recommend a solution. We don’t push the option that is easier for us — we advise the one that technically is the best choice for your property.

When should you consider internal pipe rehabilitation?

In most apartment buildings with 20, 30 or more years, you start to notice certain signs showing that the internal network is wearing down. Some appear slowly, others from one day to the next. It’s usually time to consider internal rehabilitation when you notice:

-

Recurring leaks, even after several small repairs

-

Moisture or water stains between floors, especially near vertical stacks

-

Persistent bad smells, even after normal cleaning of drains and siphons

-

Old stoneware, cast iron or early-generation PVC pipes, already worn by time

-

loose joints, small cracks, humidity patches, or unusual noises when draining

The earlier you act, the less invasive the intervention needs to be. In many cases, we can save and restore the existing pipes, without replacing them, extending their lifespan for several more decades.

How the process works

Internal rehabilitation involves several steps that must be done with care and method. It’s not just “applying some resin”, as some companies do — there is a technical process behind it that ensures a reliable and long-lasting result.

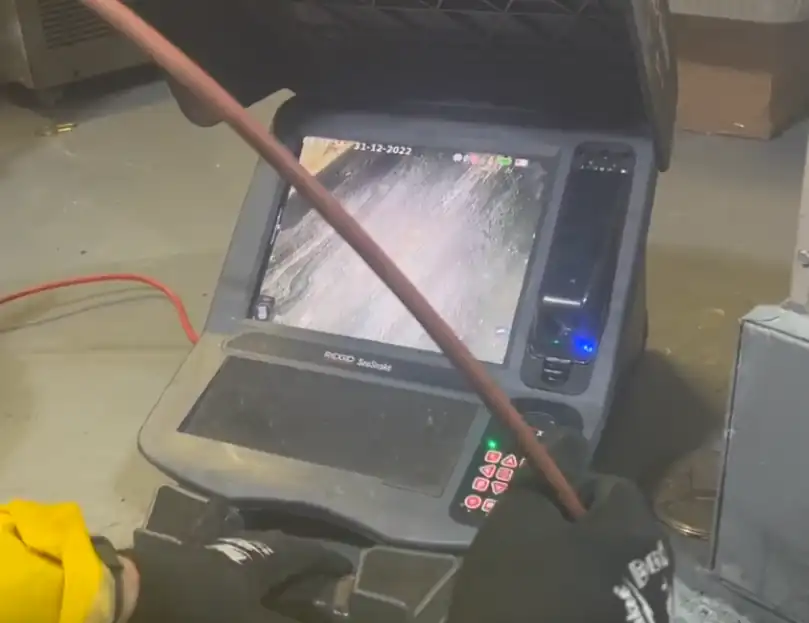

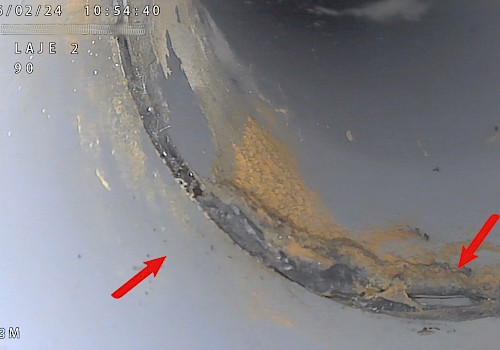

1. Diagnostic with video inspection

We always start with a camera inspection to see the real condition of the pipe. We record and identify cracks, loose joints, debris, roots or worn areas. We show everything to the client — nothing is based on guesswork.

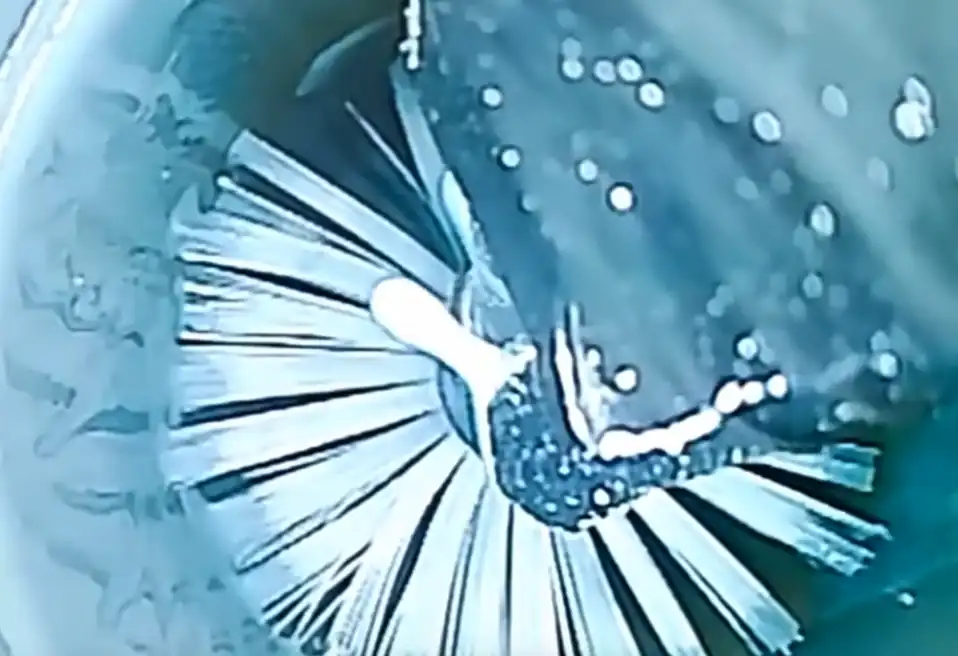

2. Cleaning and preparing the inside of the pipe

Before any application, it’s essential to prepare the pipe correctly. We use specialised equipment to remove grease, limescale, rust and residues that have built up over the years. In many cases, we do a light abrasion to create better adhesion, ensuring the lining bonds as it should.

3. Testing and pre-application evaluation

We only proceed once the pipe is clean, dry, and ready to receive the lining. We measure diameters, evaluate joints, fragile points, and plan which method to apply — continuous, spot repair or structural.

This stage is critical and is what separates a long-lasting result from a short-term fix.

The solutions we offer

Because we work with the main modern rehabilitation methods, we can adapt the solution to the problem — not the other way around. Here are the three main types:

1. Continuous epoxy lining (spraying or brushing)

Ideal to restore a full pipe when the damage or wear is general but the base structure is still stable. We create a new inner wall with epoxy resin, applied continuously (by spraying) or using controlled brushing.

Experience and sector studies show durability of 40–50+ years when the process is correctly executed. It’s a clean, quick, no-demolition solution, especially suitable for vertical stacks and interior networks in apartment buildings.

2. Localised repairs (without demolition)

When the issue is limited to a specific point — a loose joint, a crack, or a damaged small section — it doesn’t make sense to rehabilitate the entire line. In those cases, we carry out localised repairs with structural resins or small patches applied only where the anomaly is. It’s fast, cost-effective, and avoids unnecessary intervention elsewhere.

3. CIPP lining (structural cured-in-place liner)

Here, we literally create a “new pipe inside the old one”. This solution is best when there are multiple failures, material loss or structural weakness. The liner is impregnated with resin, inserted into the pipe and then cured (hardened) in place, forming a new self-supporting pipe.

How we help you choose the right solution

One of the biggest concerns people have is making the wrong decision — spending money on a solution that doesn’t really solve the issue.

This is why, at REVIPOX, we follow a very clear approach: first we show, then we explain, and only after that do we recommend.

After the video inspection and technical analysis, we present the possible options in a simple and honest way, with the pros, limitations, and approximate costs of each. If more than one solution is viable, we explain where it makes sense to save and where it is not worth taking risks. The goal is always the same: solve the problem safely, with the least impact possible for the building and for the people living in it.

We don’t “push” the most expensive option or the easiest one for us.

Being honest in this stage is what builds trust and peace of mind for our clients.

Benefits for apartment buildings and occupied properties

The biggest strength of internal pipe rehabilitation is being able to solve serious issues without turning the building into a construction site.

For apartment buildings and lived-in homes, this makes a huge difference:

-

No demolition, no dust, no heavy noise

-

Residents can usually continue using their home with minimal disruption

-

Work is planned in phases to reduce any water downtime

-

No damage to bathrooms, kitchens or common areas

-

Increases property value and protects the building for decades

It also helps avoid conflicts between neighbours and extra costs for finishing repairs (painting, tiles, ceilings, etc.), which often end up more expensive than the pipe repair itself.

Why choose REVIPOX

There are several companies that “apply epoxy” or “install liners”. But the real difference is in how and why the work is done.

At REVIPOX, we bring together three pillars that we consider essential for this kind of service:

1. Modern, low-disruption technology

We constantly invest in updated equipment and methods that allow us to fix internal pipes without demolition. Our priority is to preserve the property and the comfort of the people living in it.

2. Honest and transparent guidance

We know this is not a small decision. That’s why we explain everything clearly, with images and facts, so the client understands what is being done and why. The final recommendation is always the one that best serves the building — not the one that “suits us more”.

3. Work carried out by our own trained specialists

We do not outsource this type of intervention. All applications are carried out by our own trained technicians who specialise in this field. This ensures full control of the process and quality from start to finish.

In the end, it’s not just a repair — it’s giving a new life to your pipelines, allowing them to work properly for many more years and avoiding unnecessary construction work.

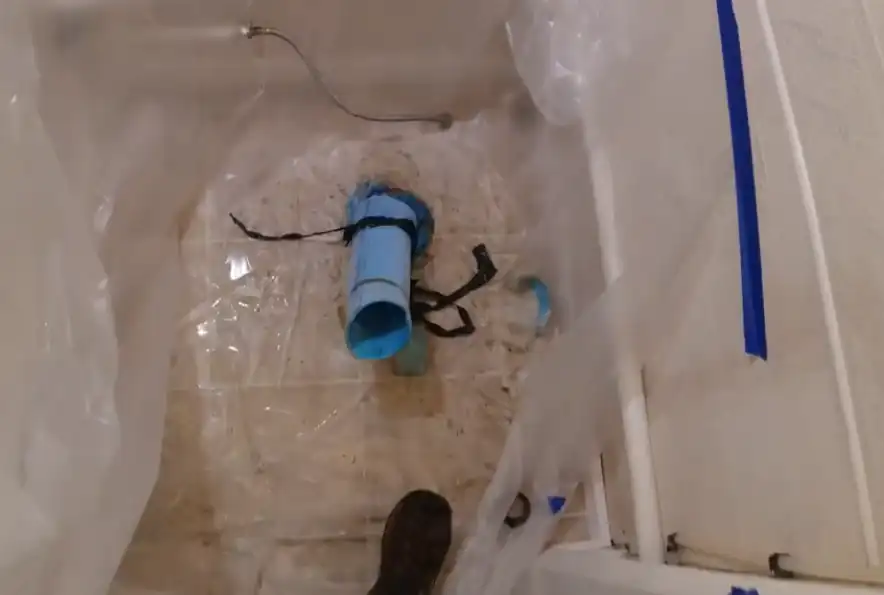

Shower base leaks - no-demolition rehabilitation

Fugas na base de duche são frequentemente causadas por falhas na ligação entre o ralo e a tubagem. A REVIPOX realiza diagnóstico técnico e, quando viável, reabilitação interna localizada sem necessidade de demolições.

CIPP Epoxy Lining

In this method, a flexible liner impregnated with epoxy resin is inserted into the existing pipe and, through pressure and heat, it is molded and cured in place, forming a new internal structural pipe.

Old Pipe Rehabilitation with Epoxy

Instead of full replacement — costly and invasive — REVIPOX offers a clean, modern alternative: internal epoxy rehabilitation, which restores the strength, flow, and watertightness of existing pipes.

Water Leak Repair with Epoxy Lining

With the REVIPOX method, leaks are eliminated without demolition, using internal epoxy coating that seals the pipeline from within and restores full watertightness.

Pipe Burst Repair with Epoxy

With the CIPP or continious epoxy lining methods, it’s possible to repair internal ruptures without demolition, using structural epoxy coatings that restore the pipe’s interior and seal leaks permanently.

Localized Pipe Repairs

When the issue is localized — a leak, damaged joint, or small rupture — REVIPOX provides high-precision internal repair techniques using structural resins and advanced epoxy materials.

Buried Pipe Rehabilitation

Through internal epoxy coating, we rehabilitate underground pipes without trenching, restoring both structural integrity and watertightness.

Vertical Pipe Stack Lining

Using internal epoxy coating technology, we rehabilitate vertical risers and water lines in condominiums without demolition, dust, or interruption to daily routines.

Epoxy Pipe Lining

By applying a continuous protective layer inside the pipe, we create a new, resistant, and watertight inner wall that restores functionality, flow, and safety to the entire system.

Pipe Cleaning and Internal Preparation

We perform mechanical cleaning and internal preparation of pipelines using specialized technology that ensures perfect adhesion and maximum durability of the epoxy lining.

Complete solutions for internal pipe rehabilitation

At REVIPOX, we operate across all stages of the rehabilitation process — from initial inspection to final epoxy coating. Each service is carried out by specialized technicians using advanced technology, ensuring long-lasting results without the need for demolition.

Pipe Video Inspection

High-definition visual diagnostics using HD video cameras to assess the internal condition of the pipes and identify cracks, leaks, or corrosion before intervention.

Mechanical Cleaning and Internal Preparation

We remove scale, debris, and corrosion through controlled brushing and jetting, preparing the pipe surface for perfect epoxy adhesion.

Epoxy Internal Coating

Application of a continuous internal epoxy lining that creates a new protective wall inside the pipe, sealing leaks and preventing future ruptures.

Vertical Pipe and Riser Rehabilitation

An ideal solution for buildings and condominiums, allowing the renewal of vertical water and wastewater risers without opening walls or disrupting residents. Fast, clean, and completely trenchless.

Buried Pipeline Rehabilitation

Internal coating of underground sewer, drainage, or stormwater pipes, eliminating leaks and maintaining structural integrity — no excavation required.

Localized Repairs and Leak Sealing

Targeted repair of internal ruptures, damaged joints, or small leaks using high-adhesion structural resins — a quick, clean, and long-lasting solution.

Contacto e pedido de diagnóstico

Problemas nas tubagens? Podemos ajudar sem obras.

100%

Guaranteed Satisfaction

We rehabilitate pipelines, we restore confidence

REVIPOX is a company specialized in internal epoxy pipe coating, a technology that allows the restoration of aging pipelines without demolition. With trained teams and state-of-the-art equipment, we bring back functionality, durability, and safety to water and wastewater systems in residential, commercial, and industrial buildings.

-

-

Certified technology and long-lasting materials

-

Solutions adapted to every network type and diameter (32 mm to 300 mm)

The REVIPOX Method - New Life For Your Pipes

Why to choose REVIPOX?

Trust the experts who bring new life to your pipelines.

REVIPOX combines technology, precision, and experience to deliver long-lasting epoxy pipe rehabilitation solutions — with no need for demolition. Our work is based on detailed diagnostics, certified materials, and qualified technicians who ensure results that last.

Experienced Team

Our specialists are trained in internal epoxy coating and use advanced inspection and application equipment to guarantee top-quality results every time.

Trusted and Transparent

From the first contact to project completion, we value clear communication and trust. Every client receives a technical report and full professional support throughout the process.

Latest News & Articles from REVIPOX

Follow the REVIPOX Blog to explore the latest updates in epoxy pipe rehabilitation, trenchless technology, and modern solutions for aging pipeline systems. We share technical tips, real case studies, and industry insights for those who want to stay informed about innovation in pipeline restoration.

Continuous internal rehabilitation in ageing pipe systems

When joint seals degrade across a pipe system, continuous internal rehabilitation restores watertightness and extends service life without full replacement.

Read More

Old joint seals in plastic pipes

PVC joints may appear intact during inspection yet still allow infiltration. This article explains the ageing process, warning signs, and appropriate technical solutions.

Read More

Rehabilitate or Replace Building Drains? What to Assess Before Deciding

Replace or rehabilitate drainage stacks? Learn what should be assessed before starting major building works.

Read More