Fast interventions with no demolition required

Prepare today to protect tomorrow

Before applying the internal epoxy coating, it is essential to ensure that the pipe walls are completely clean, dry, and uniform.

At REVIPOX, we perform mechanical cleaning and internal preparation of pipelines using specialized technology that ensures perfect adhesion and maximum durability of the epoxy lining.

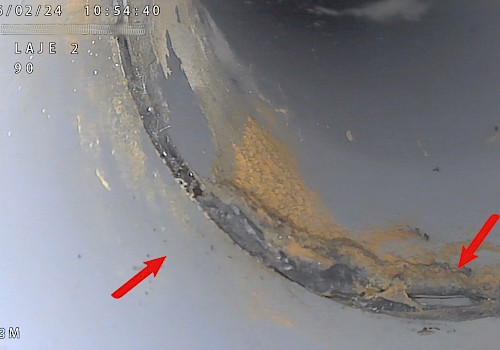

In Portugal, most sewer networks are made of stoneware or plastic pipes (PVC and PP), especially in newer urban areas. In the older parts of cities like Lisbon, Porto, or Coimbra, we still find many vitrified clay pipes, with aged joints that have weakened over time. Each material requires a different approach during internal cleaning and preparation. Plastic pipes, for example, cannot withstand the same pressure as stoneware and must be cleaned with equipment that allows precise control of force and temperature to avoid deformation. Stoneware, on the other hand, is mechanically strong but fragile at the joints and can crack if hit directly. That’s why we use adjustable tools, brushes suited to each diameter, and controlled pressure — ensuring a thorough cleaning without compromising the pipe’s integrity.

This preparation stage is what separates a simple repair from a professional and long-lasting rehabilitation.

Every step is carried out by experienced technicians using rotary brushes, controlled jetting, and forced drying, restoring the internal condition of the pipeline to guarantee optimal bonding of the epoxy layer.

How the cleaning process works

-

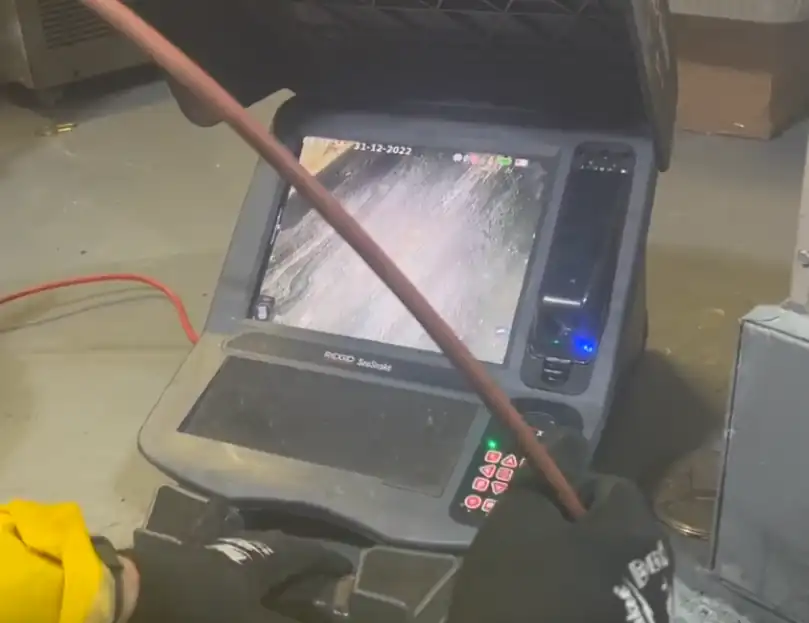

Initial video inspection: before starting the cleaning, we assess the pipe’s interior to locate corrosion, debris, and critical sections.

-

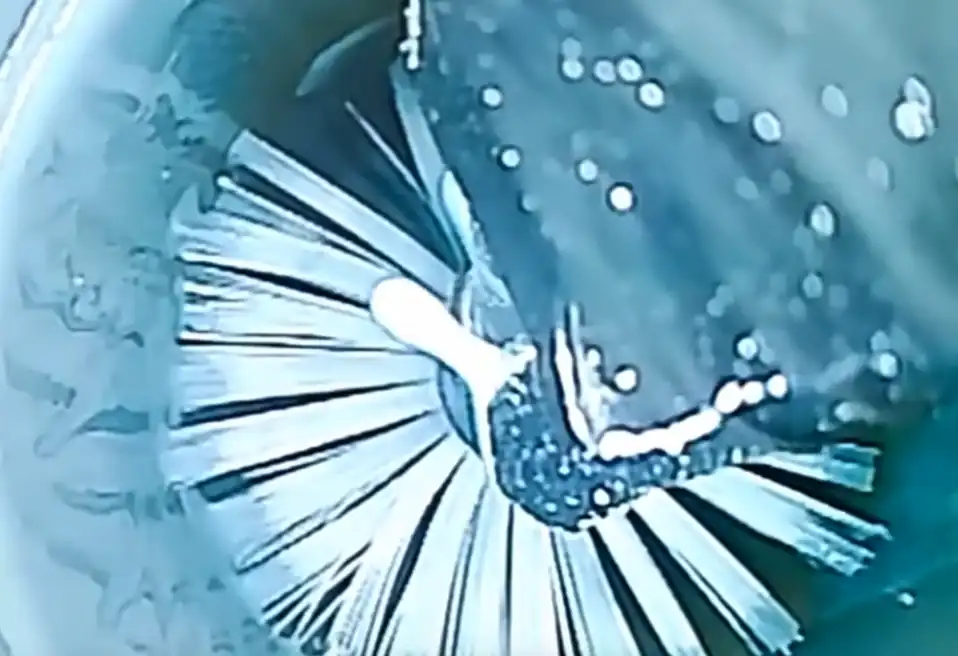

Rotary mechanical brushing: we use calibrated brushes that remove rust, scale, grease, and deposits without damaging the pipe walls.

-

Jet cleaning and internal polishing: when necessary, we perform controlled jetting with fine abrasives to create a smooth, uniform surface.

-

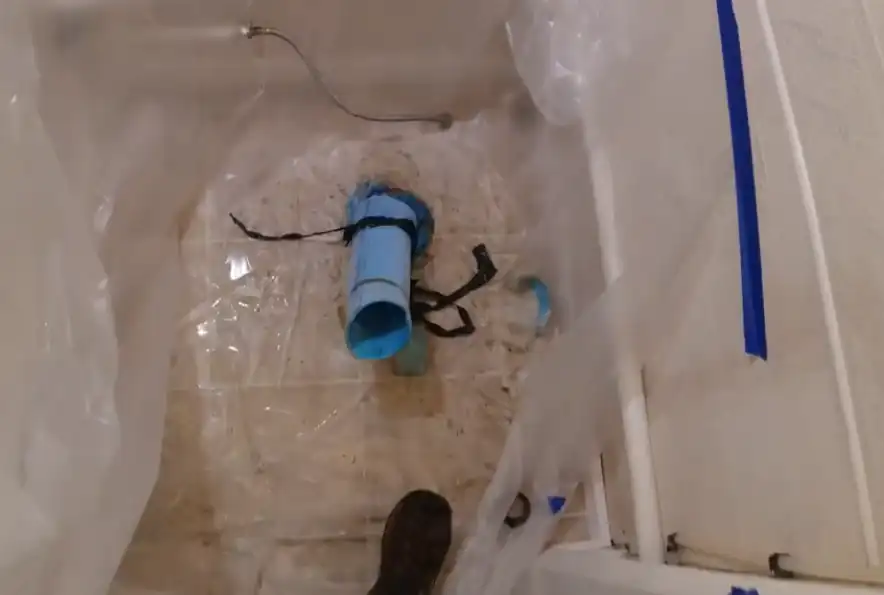

Drying and final verification: after cleaning, the pipe is dried with compressed air and re-inspected to ensure a clean, adhesive-ready surface.

Benefits of REVIPOX internal cleaning and preparation

-

Superior adhesion for the epoxy coating

-

Extended durability and corrosion resistance

-

Complete removal of old deposits and residues

-

Reduced risk of future leaks or ruptures

-

Fast, clean, and non-invasive process

When this service is needed

A slight abrasion of the internal pipe walls is an essential step before continuous epoxy application. This process removes scale, old grease, and small loose layers of limestone or rust that would prevent the resin from fully bonding. It also creates a slightly rough surface, ideal for mechanical adhesion of the new coating. Without this preparation, the resin could form a thin film over debris, reducing the system’s durability and watertightness. The goal isn’t to wear down the pipe but to ensure the epoxy bonds evenly and permanently, making the new inner wall an integral part of the original structure.

Internal cleaning and preparation is recommended before any epoxy internal coating or pipeline rehabilitation, especially in:

-

Aged galvanized, copper, or PVC pipes

-

Vertical risers in residential and commercial buildings

-

Buried pipes with accumulated residue

-

Industrial or commercial conduits exposed to chemicals or temperature changes

Preparation means intelligent rehabilitation

At REVIPOX, we believe that the longevity of a rehabilitated pipeline depends on the quality of its preparation.

That’s why every project is executed with precision tools and technical rigor, ensuring that the epoxy coating bonds perfectly and remains effective for decades.

REVIPOX — Prepare today to protect tomorrow.

100%

Guaranteed Satisfaction

We rehabilitate pipelines, we restore confidence

REVIPOX is a company specialized in internal epoxy pipe coating, a technology that allows the restoration of aging pipelines without demolition. With trained teams and state-of-the-art equipment, we bring back functionality, durability, and safety to water and wastewater systems in residential, commercial, and industrial buildings.

-

-

Certified technology and long-lasting materials

-

Solutions adapted to every network type and diameter (32 mm to 300 mm)

The REVIPOX Method - New Life For Your Pipes

Contacto e pedido de diagnóstico

Problemas nas tubagens? Podemos ajudar sem obras.

Complete solutions for internal pipe rehabilitation

At REVIPOX, we operate across all stages of the rehabilitation process — from initial inspection to final epoxy coating. Each service is carried out by specialized technicians using advanced technology, ensuring long-lasting results without the need for demolition.

Pipe Video Inspection

High-definition visual diagnostics using HD video cameras to assess the internal condition of the pipes and identify cracks, leaks, or corrosion before intervention.

Mechanical Cleaning and Internal Preparation

We remove scale, debris, and corrosion through controlled brushing and jetting, preparing the pipe surface for perfect epoxy adhesion.

Epoxy Internal Coating

Application of a continuous internal epoxy lining that creates a new protective wall inside the pipe, sealing leaks and preventing future ruptures.

Vertical Pipe and Riser Rehabilitation

An ideal solution for buildings and condominiums, allowing the renewal of vertical water and wastewater risers without opening walls or disrupting residents. Fast, clean, and completely trenchless.

Buried Pipeline Rehabilitation

Internal coating of underground sewer, drainage, or stormwater pipes, eliminating leaks and maintaining structural integrity — no excavation required.

Localized Repairs and Leak Sealing

Targeted repair of internal ruptures, damaged joints, or small leaks using high-adhesion structural resins — a quick, clean, and long-lasting solution.

Why to choose REVIPOX?

Trust the experts who bring new life to your pipelines.

REVIPOX combines technology, precision, and experience to deliver long-lasting epoxy pipe rehabilitation solutions — with no need for demolition. Our work is based on detailed diagnostics, certified materials, and qualified technicians who ensure results that last.

Experienced Team

Our specialists are trained in internal epoxy coating and use advanced inspection and application equipment to guarantee top-quality results every time.

Trusted and Transparent

From the first contact to project completion, we value clear communication and trust. Every client receives a technical report and full professional support throughout the process.

Latest News & Articles from REVIPOX

Follow the REVIPOX Blog to explore the latest updates in epoxy pipe rehabilitation, trenchless technology, and modern solutions for aging pipeline systems. We share technical tips, real case studies, and industry insights for those who want to stay informed about innovation in pipeline restoration.

Continuous internal rehabilitation in ageing pipe systems

When joint seals degrade across a pipe system, continuous internal rehabilitation restores watertightness and extends service life without full replacement.

Read More

Old joint seals in plastic pipes

PVC joints may appear intact during inspection yet still allow infiltration. This article explains the ageing process, warning signs, and appropriate technical solutions.

Read More

Rehabilitate or Replace Building Drains? What to Assess Before Deciding

Replace or rehabilitate drainage stacks? Learn what should be assessed before starting major building works.

Read More